Blade Problem Solve

Blade failures are never good for any hobbyist and or manufacturer. There are many elements that can cause a failing blade. In this section you will be able to observe your current broken blade or even a blade that seems to be looking unusual after run time.

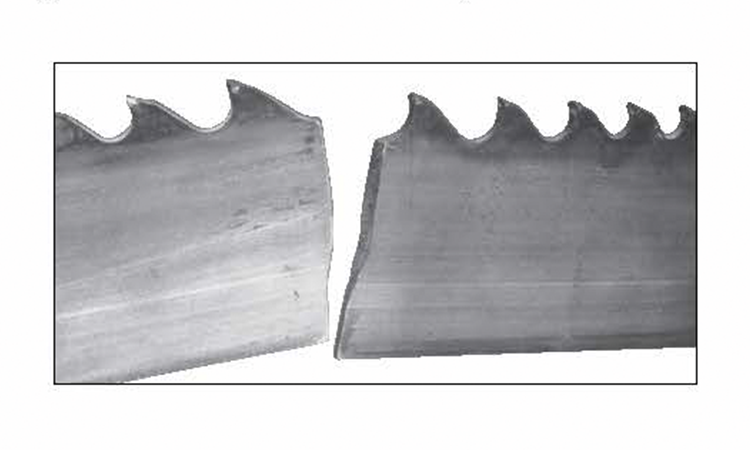

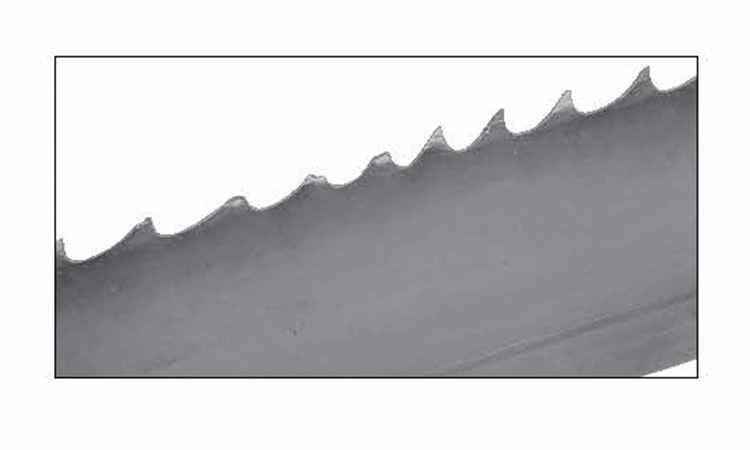

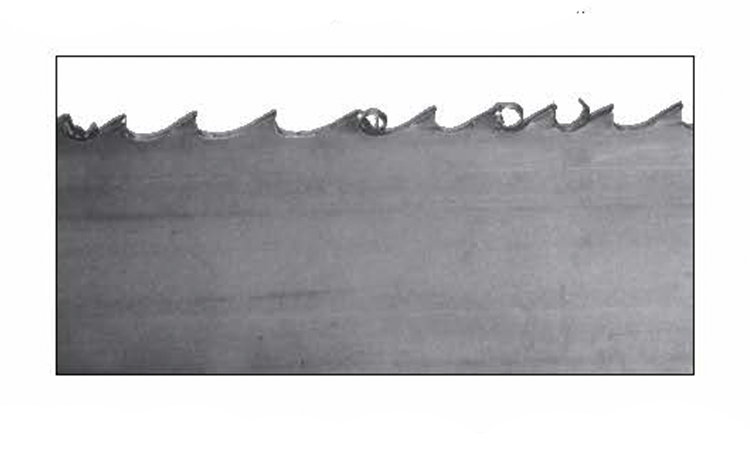

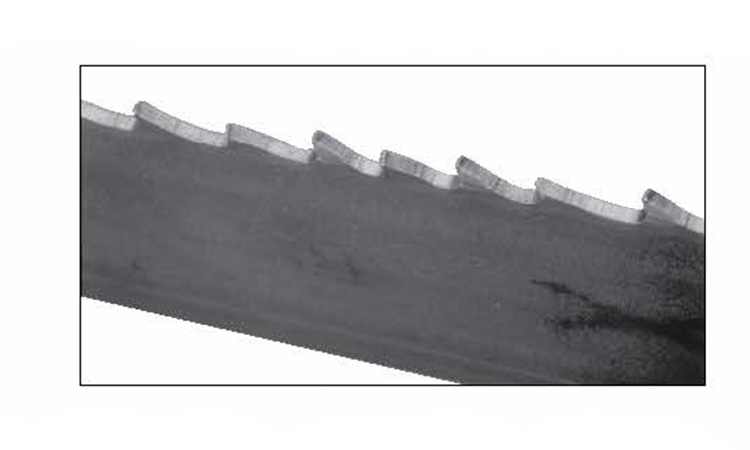

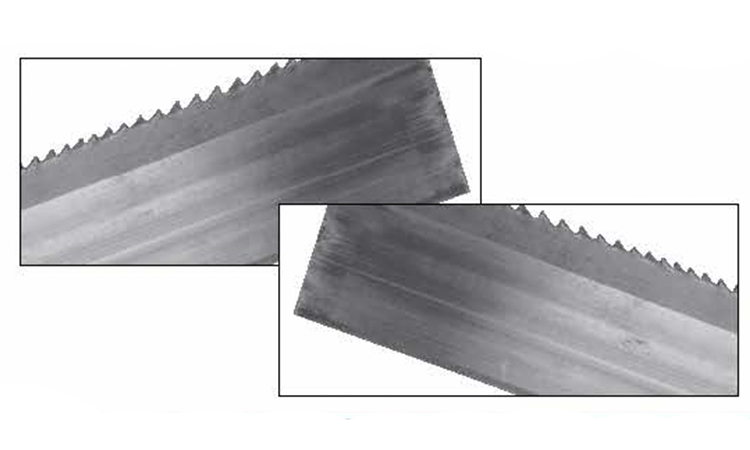

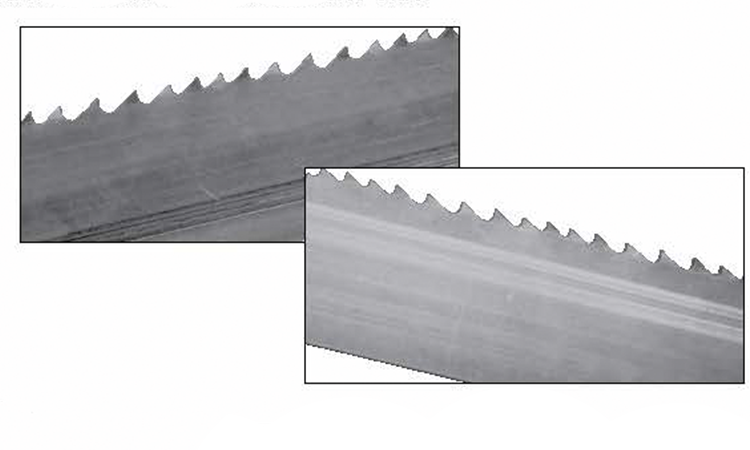

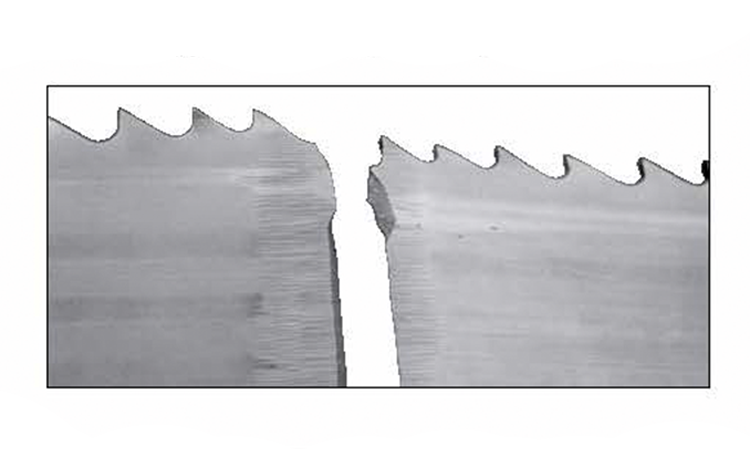

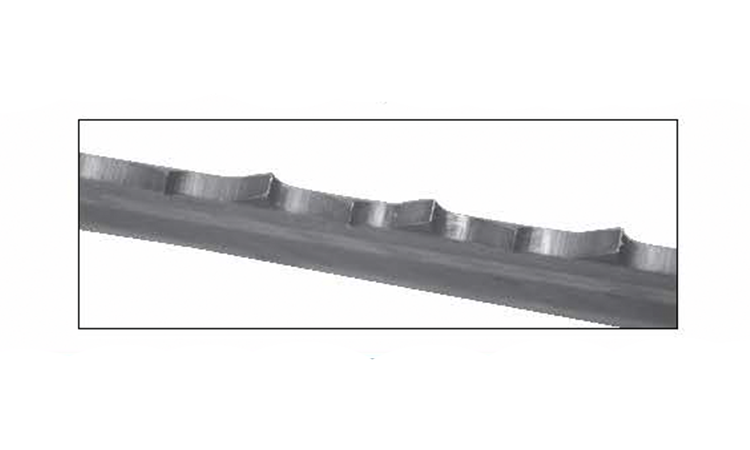

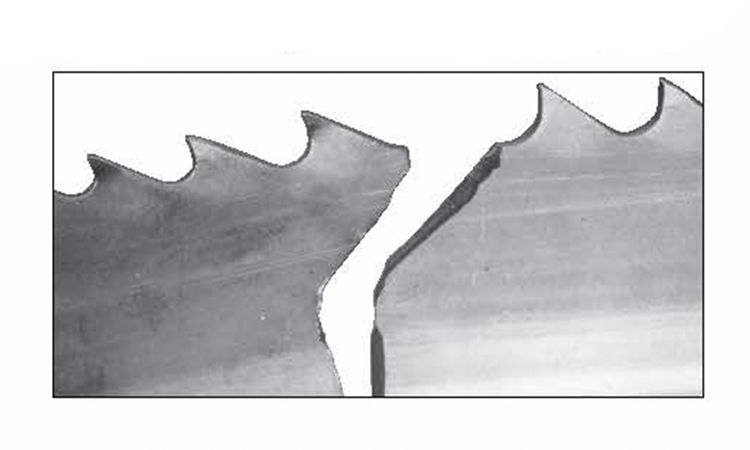

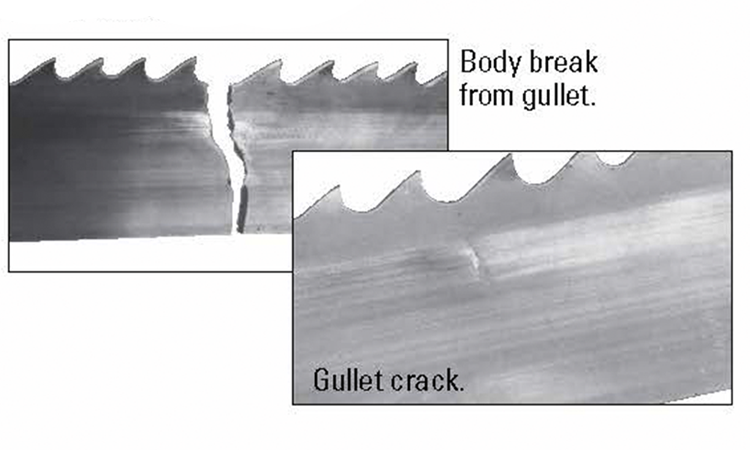

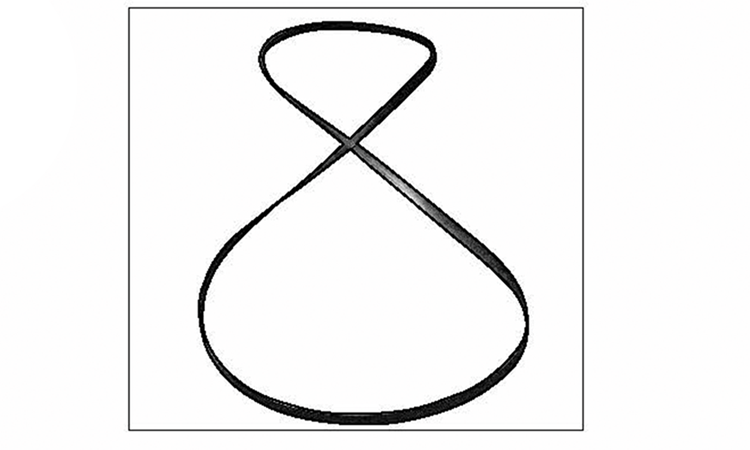

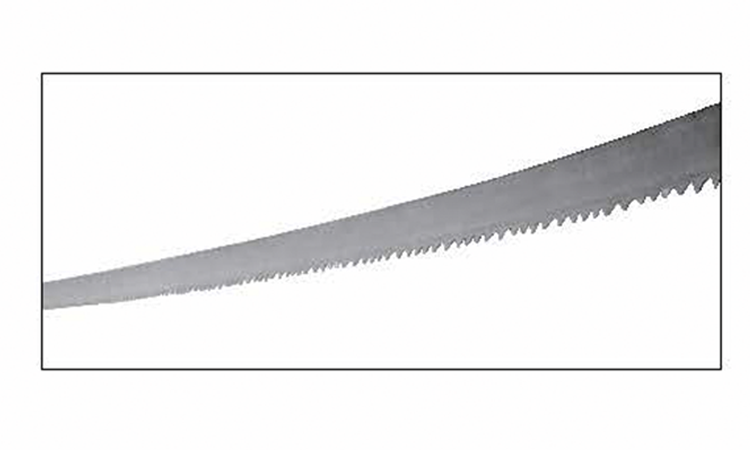

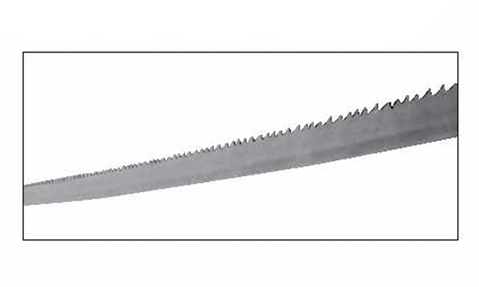

Based off of looking at the blade, what is the current issue? Did it break? Does it have heavy wear on the sides? Chipped teeth or even cracks?

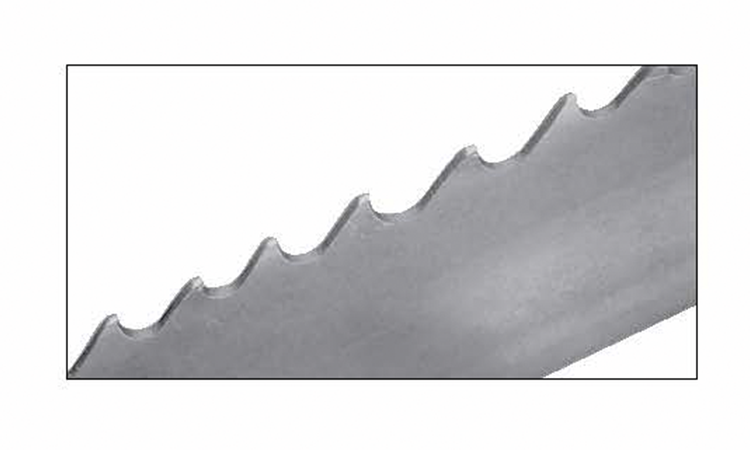

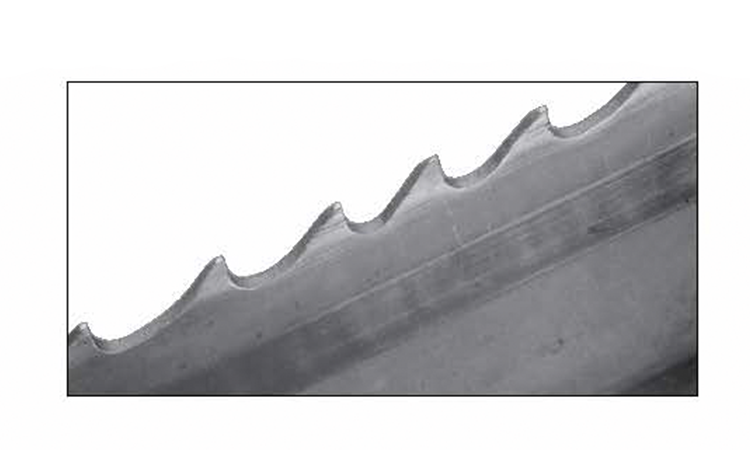

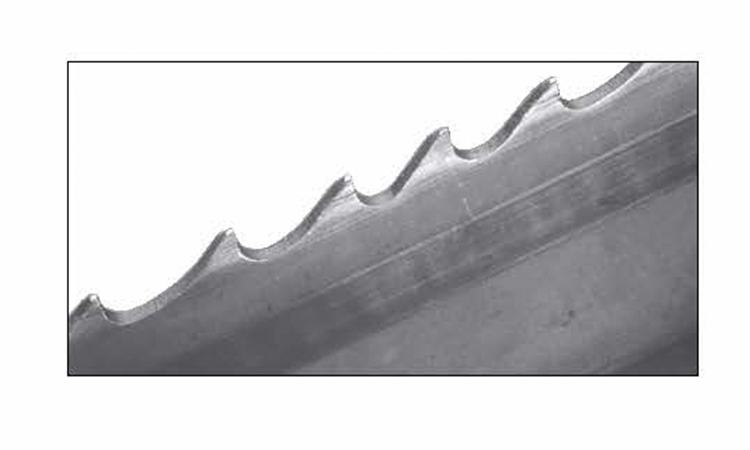

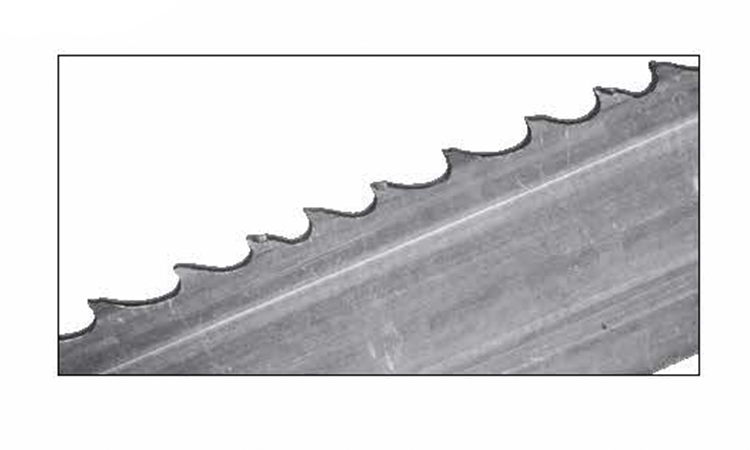

Knowing the issue of the blade, click on what best describes the issue with the blade or find the image that best matches what you are observing and learn what the cause of the failed blade is. Below is a list of Observations 1-20.