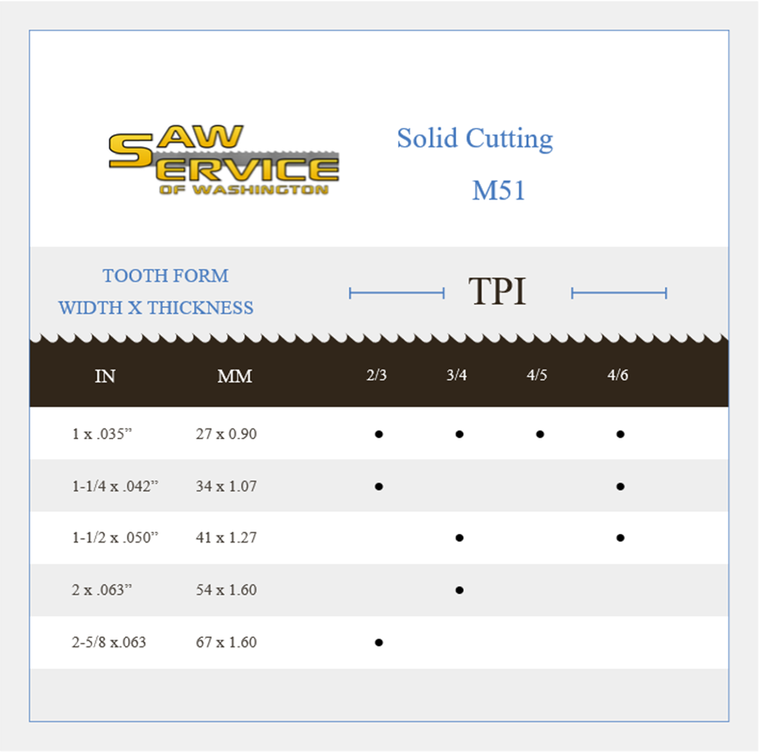

BI-METAL M51

|

|

Specifically designed for cutting stainless, nickel, inconel, monel and titanium alloys. The teeth are formed using a superior steel alloy with 10% cobalt and 10% tungsten.

This alloy substantially improves heat and fatigue resistance in high-speed cutting applications resulting in longer life of the blade, cutting accuracy and cost effectiveness. |

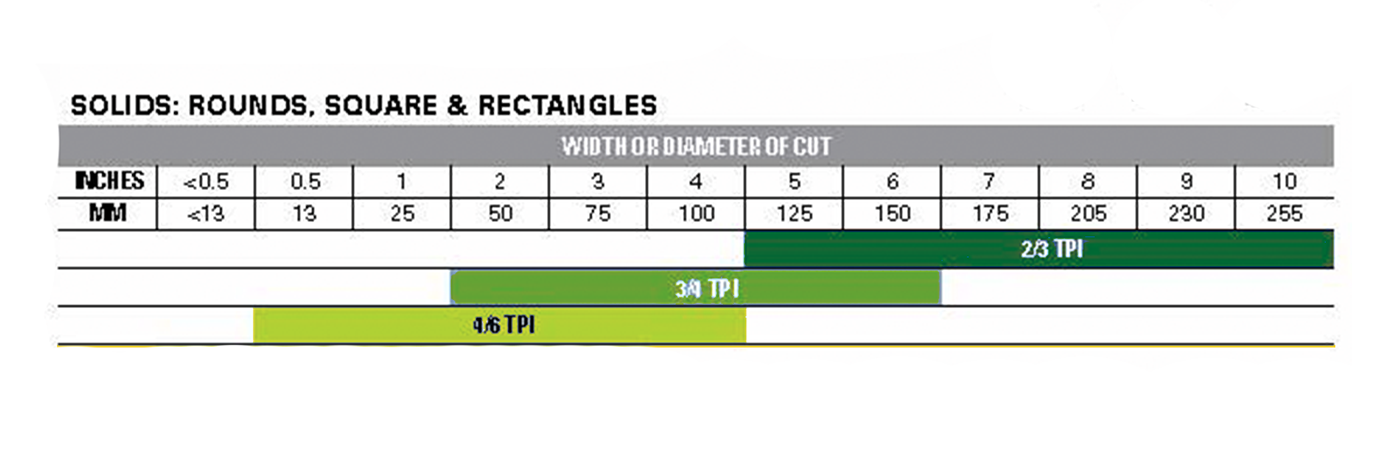

TPI HELP CHART

Solid Cutting Only

1. Determine size and shape of material to be cut

2. Identify chart to be used (square solids, round solids, or rectangles)

3. Read teeth per inch next to material size.

2. Identify chart to be used (square solids, round solids, or rectangles)

3. Read teeth per inch next to material size.