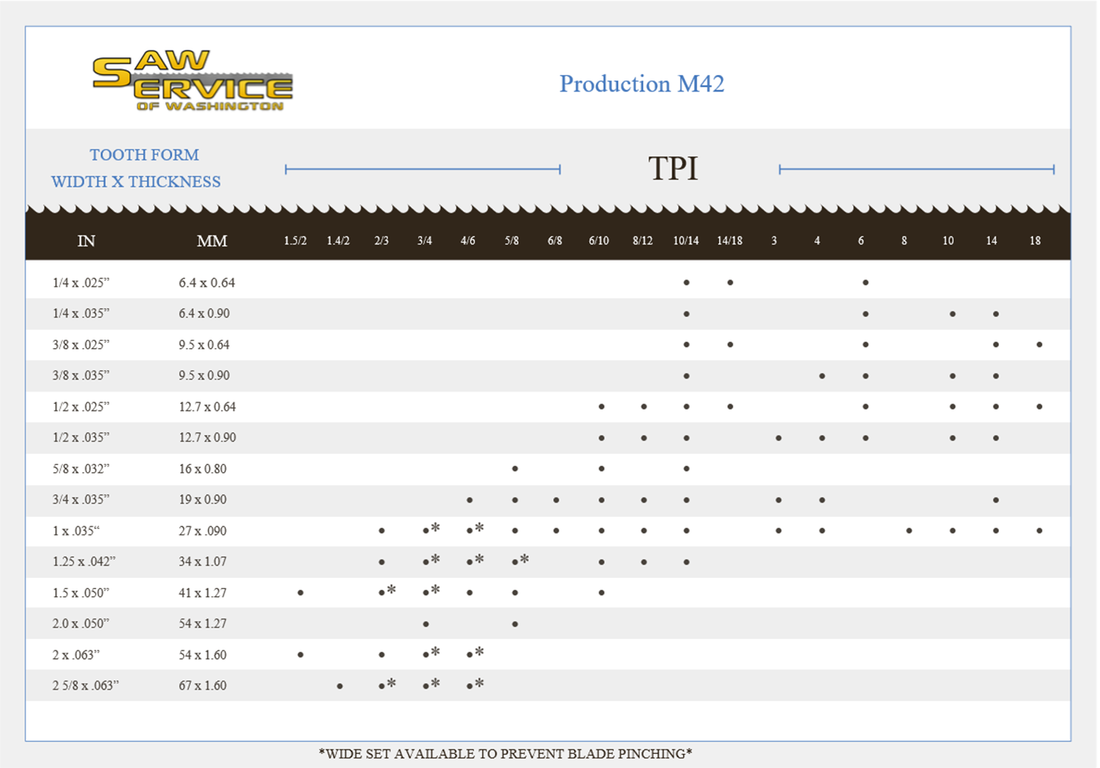

PRODUCTION M42 BI-METAL / WIDE SET M42

|

|

Production M42

This multi-use blade is ideal for cutting all kinds of steel, both ferrous and nonferrous such as carbon, chrome, tool, die, stainless steel and nickel base steel. Cutting performance across a broad range of applications and materials is achieved through tooth geometries, providing optimal durability and versatility at high speeds. Variable teeth are recommended for cutting tubing and structural material, but can also be used for solid materials. This blade is ideal for fabricators, tool and die shops, medium and large manufacturers and in steel service centers. Wide Set M42 Designed for cutting bundles, profiles and tubes. It can handle even the largest cross section profiles while avoiding blade pinching during the cut. The tooth geometry maximizes cutting performance while minimizing kerf loss. This design also produces faster cutting rates and increases productivity with less noise, a smoother finish and longer blade life. |

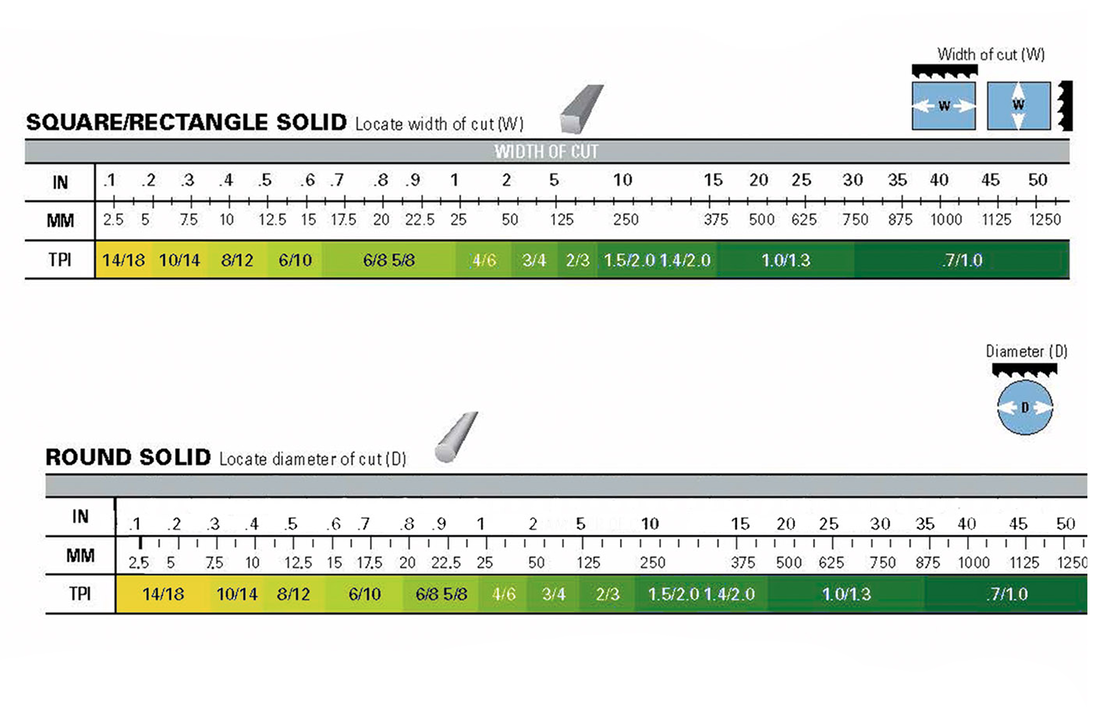

TPI HELP CHART

The charts below will help you determine the best TPI to use for the cutting application.

1. Determine size and shape of material to be cut

2. Identify chart to be used (square solids, round solids, or tubing/structural)

3. Read teeth per inch next to material size.

2. Identify chart to be used (square solids, round solids, or tubing/structural)

3. Read teeth per inch next to material size.